Category

Date Posted

March 7, 2025

/

0 Comment

CONTEXT: Concerns regarding the Ethanol Blended Petrol (EBP) initiative continue to persist in Andhra Pradesh. Scientists and farmers have raised alarms about the depletion of water resources and the pollution of air, water, and soil caused by emissions from factories.

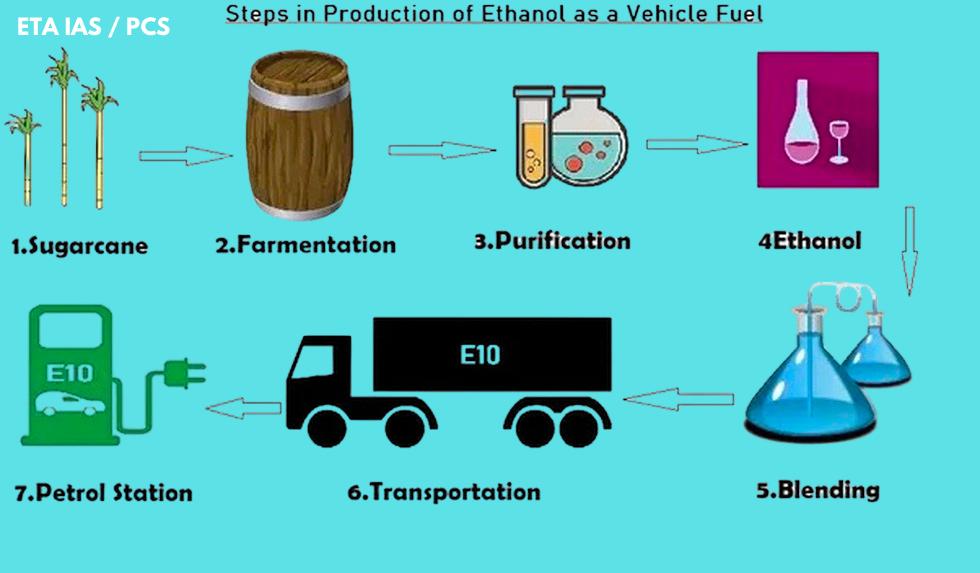

Definition of Ethanol Blending:

- Ethanol blending refers to the process of incorporating ethanol, a form of alcohol and biofuel, into petrol to create a blended fuel.

Common Ethanol-Petrol Mixtures:

- The most common ethanol blend is E10, which consists of 10% ethanol and 90% petrol.

- A more concentrated variant is E20, which contains 20% ethanol and 80% petrol.

Methods of Ethanol Production:

- Ethanol can be produced through the fermentation of sugars by yeast, a biological process.

- It can also be produced via petrochemical methods, such as the hydration of ethylene.

Ethanol Blending Programme in India:

- India launched the Ethanol Blending Programme (EBP) in 2003.

- The main objectives of the programme include:

- Reducing reliance on crude oil imports.

- Lowering carbon emissions.

- Enhancing the income of farmers.

National Policy on Biofuels (2018):

- The National Policy on Biofuels, established in 2018, set the following targets:

- Achieve 20% ethanol blending in petrol.

- Achieve 5% biodiesel blending in diesel.

- The target for achieving these goals was initially set for 2030.

- The National Policy on Biofuels, established in 2018, set the following targets:

Acceleration of Blending Targets:

- The government accelerated the timeline for achieving the 20% ethanol blending target from 2030 to the Ethanol Supply Year (ESY) 2025-26.

Key Milestones in the Blending Programme:

- In 2022, the ethanol blending programme reached 10% ethanol blending in petrol.

- As of 2024, the blending percentage increased to 15%.

Sources of First-Generation (1G) Ethanol:

- First-generation (1G) ethanol is derived from:

- Food crops like sugarcane.

- Food grains such as broken rice and corn.

- First-generation (1G) ethanol is derived from:

1. Depletion of Water Resources:

- The production of ethanol requires 8 to 12 liters of water for every liter of ethanol produced.

- Over-reliance on groundwater sources is reducing the availability of water for both drinking and agricultural purposes.

- Facilities located near rivers, such as the Krishna River in Andhra Pradesh, are contributing to the strain on already limited water supplies.

2. Pollution from Ethanol Manufacturing:

- Ethanol production facilities are categorized as ‘red category’ industries, meaning they are highly polluting (pollution score > 60).

- These plants release hazardous substances like acetaldehyde, formaldehyde, and acrolein, contributing to contamination of air, water, and soil.

- Health risks are significant due to the pollution caused by these factories, especially in areas like East Godavari, Krishna, and NTR districts of Andhra Pradesh.

- Lokayukta officials have raised concerns regarding insufficient pollution control measures at ethanol plants in these regions.

3. Threats to Food Security:

- The primary source of ethanol is grain-based, such as maize, which is being increasingly cultivated for ethanol production.

- This practice reduces the land available for food crops, posing a threat to food security, as large portions of agricultural land are diverted for fuel production instead of food production.

4. Greenhouse Gas Emissions from Ethanol Feedstock:

- The shift in agricultural focus from food crops to fuel production leads to an increase in greenhouse gas (GHG) emissions from the agricultural sector.

- This undermines efforts to reduce emissions in the transportation sector, as the benefits of ethanol blending are offset by the increased emissions in food crop production.

5. No Decrease in Nitrogen Oxide Emissions:

- While ethanol-blended petrol results in a reduction of carbon monoxide emissions, it does not lead to a reduction in nitrogen oxide (NOx) emissions.

- Nitrogen oxides are significant environmental pollutants and continue to contribute to air pollution despite the use of ethanol in petrol.

1. Conflicting Perspectives:

Government and Industry Perspective:

- According to NITI Aayog, a 20% ethanol blend can lead to:

- A 30% reduction in carbon monoxide emissions from four-wheelers.

- A 50% reduction in carbon monoxide emissions from two-wheelers.

- However, industrialists argue that implementing pollution control measures:

- Increases production costs.

- Makes compliance with regulations more complicated and challenging.

Environmentalists’ Perspective:

- Environmentalists acknowledge that biofuels like ethanol can reduce vehicular emissions.

- However, they point out that:

- The ethanol production process itself can be highly polluting if not managed properly.

- Ethanol production could negatively affect:

- Agriculture (e.g., diverting land from food crops).

- Water resources (e.g., excessive water usage).

- Public health (e.g., pollution and contamination from ethanol plants).

2. Path Forward:

Enhanced Pollution Monitoring:

- Emission impact assessments should be an integral part of the clearance process for new ethanol production plants. This ensures that environmental concerns are addressed before operations begin.

Sustainable Water Management:

- Regulations on groundwater usage for ethanol production facilities should be enforced strictly to minimize the depletion of water resources.

Sustainable Biofuels:

- Sustainable biofuels made from crop residues and other low-impact sources have a reduced water and greenhouse gas footprint compared to first-generation biofuels.

- The Global Biofuels Alliance initiative aims to encourage the development of these sustainable alternatives and promote the use of ethanol derived from less environmentally demanding sources.

Balancing Industrial Growth with Environmental Safety:

- It is crucial to ensure that pollution control measures for ethanol production plants are both economically viable and effective in mitigating environmental damage. This will help balance the goals of industrial growth with environmental safety.